The Basics About Recycled Rubber

What Is Recycled Rubber?

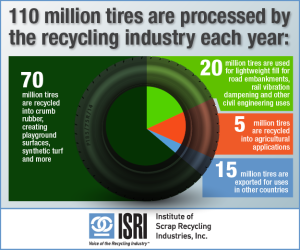

Today more than recycling keeps more than 110 million tires out of landfills each year. Materials like fiber and wire are moved and the rubber is cleaned, and then the rubber is typically ground into what is called crumb rubber. The recycled rubber can then be used for a wide variety of applications, including in synthetic turf fields, hospital floors, roads and sidewalks, and even shoes.

Recycled rubber gives us innovative ways to reduce waste while solving important challenges – from facilitating softer playground surfaces, to reducing the chance of injuries for athletes, to building lower-impact hospital floors for nurses on their feet all day.

How Is It Made?

- AMBIENT SHREDDING uses powerful, interlocking knives to chop tires into smaller pieces.

- CRYOGENIC PROCESS uses liquid nitrogen to freeze them at sub-zero temperature. These cold temperatures cause the tire to become very brittle. The tire is then placed in an enclosure in which powerful hammers smash the tire apart.

The non-rubber portions of the tire are also recycled. For example, the steel beads that give the tire its shape and structure are recovered by recyclers and processed into specification grade product used by steel mills for new steel.

At no point in the process does the rubber undergo any chemical change. In short, recycled rubber is rubber.